Our 3 specialties dedicated to your industrial projects:

OUR EXPERTISE

MECA MODELE 71 has 35 years of experience in prototype injection molds and foam molds, serving numerous industrial sectors, including renowned automotive manufacturers and suppliers.

MECA MODELE 71 handles the production and design of tooling for plastic injection molds, as well as the injection of parts.

We also design and produce foam, prototype, and production tooling.

Production workshop with a fully integrated, comprehensive offering:

From design to small and medium-scale production

Integrated design office, machining workshop, assembly workshop, plastics production unit, 3D control room

ISO 9001 / ECOVADIS Certification

Made in France – Burgundy

Recognized expertise since 1988

Team of 15 expert employees

Design office: CAD with CATIA V5, CAM with WORKNC 3 and 5 axes, ROMER control arms

Complete machine park:

2 HURON KX50L 5-axis machines, KX30 and KX20, FANUC wire EDM cutting machines, traditional milling machines and lathes, TEDERICK electric plastic injection presses from 100 tons to 1,100 tons Excellent value for money

Fair pricing

No budget overruns

From design to small and medium-scale production, we can tailor our services to your specific needs.

From large industrial groups to innovative project leaders, MECA MODELE 71 knows how to meet all industrial challenges! Respect for deadlines and specifications

Efficient and responsive customer service: your constraints are our challenges!Production in Burgundy, coverage throughout Europe 1,400m² of rooftop solar panels producing 124kWpLocal production, made in France to limit the environmental impact of transportation

Production using more responsible materials: recycled plastic, plastic made from natural fibers (e.g., hemp) All tools are designed using CAD in our in-house design office to improve efficiency and responsiveness.

The design office is staffed by four people.

We use CATIA V5 software for CAD.

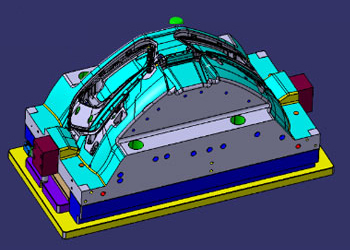

Automatic injection mold for small production

Complex mold

Prototype mold with manual shims

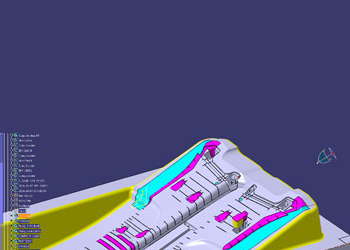

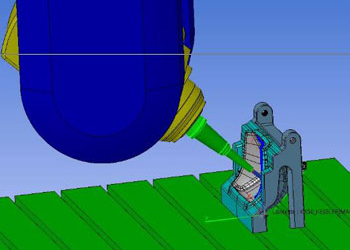

Using WORK NC software for 3 and 5 axis machining

Example of a machining simulation

Example of a machining simulation

A latest generation of machinery to carry out your projects

Injection molding of prototype and medium-volume plastic parts on our three electric presses, ranging from 100 to 1,100 tons.

We can thus guarantee maximum performance and responsiveness in the production of small series and prototype parts.

3 electric presses from 100 tonnes to 1,100 tonnes

20-ton bridge

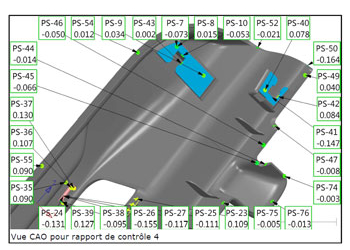

Meca Modele 71 performs part and tool inspections.

Inspection: Romer ABSOLUTE ARM 7325, 2500mm capacity, POWER INSPECT software.

POWER INSPECT software

Romer ABSOLUTE ARM 7325 capacity 2500mm

Custom solutions for the production of shapes tools and plastic injection

Copyright © 2023